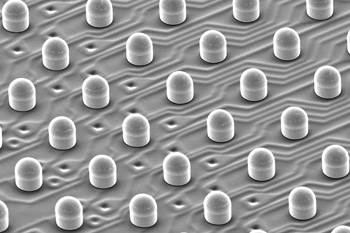

Our Copper Pillar Bump improves the packaging capability for flip chips on substrates and modules since it could reach as small as 40um fine bump pitch. Our lead-free solder tip (SnAg1.8%) fulfills RoHS and Green Product requirements. Applications: Dynamic Random Access Memory (DRAM), Memory controller, FPGA, Wi-Fi, RF Switch, Power Control IC, SAW & BAW Filter, and LEDs.

Features

- Wafer Sizes: 12-inch(300mm), 6-inch(150mm)

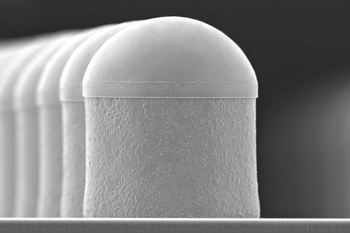

- Structure & Material: Electroplated solder with SnAg 1.8%, SnAu 80%; Polyimide curing at 200°C (low temp) and 375°C (high temp)

- Bump Pitch: 40μm and above

- Pillar Height: 75μm and below for 12-inch wafers; 90μm and below for 6-inch wafers.

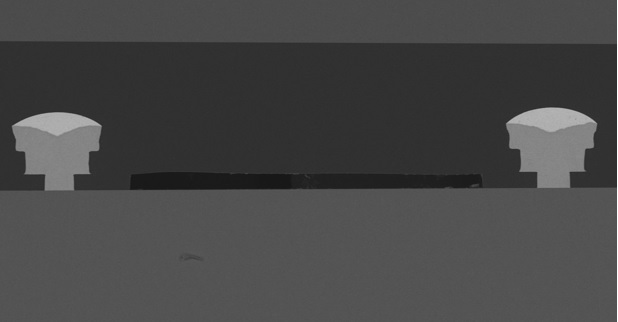

- Flexible Design: Asymmetric CPB may provide more design feasibility and enhance electrical and thermal properties.

- Dummy Bump: Provide dummy bump design service to help make flip-chip assembly applicable for chips with only central pads or very few metal pads. The dummy bump and original CPB may stand on different planes while maintaining a level bump surface via flexible bump heights. This service can help facilitate memory devices' flip-chip packaging, such as DRAM.

- Combined Application: Our CPB advantage complements SAW/BAW Filter cavities to protect the sensitive circuit/devices and their products to achieve space efficiency. The optimized features can also greatly enhance the electrical performance and broad application of 5G.

- Turnkey Solution: Provide WLCSP Turnkey Service, including Bumping, Test, Grinding, Dicing, Tape & Reel.

Applications

- Applicable Products: DRAM, Memory controller, FPGA, WiFi, RF Switch, Power Control IC, SAW and BAW Filter, LED...

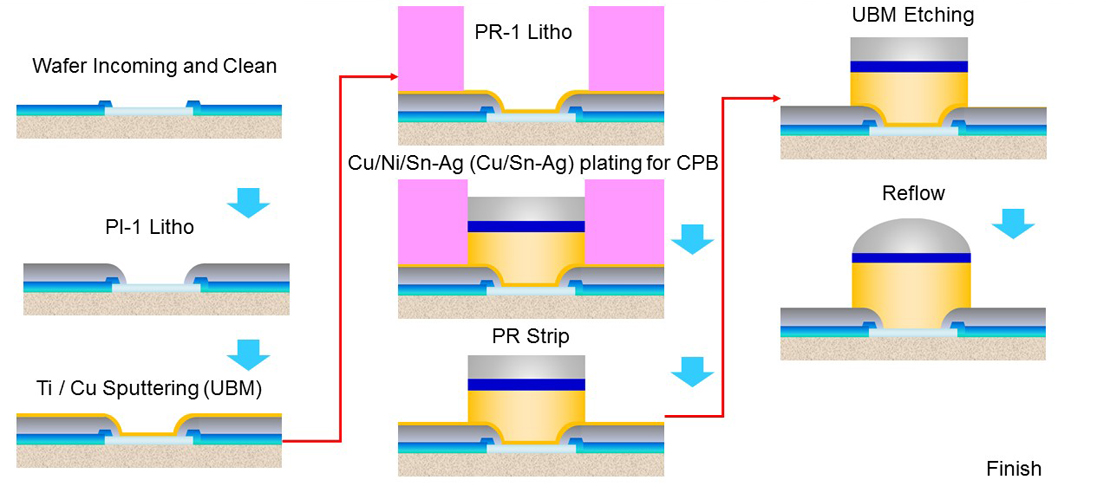

Cu Pillar Bump Process Flow